AstraZeneca

This case study looks at how AstraZeneca reassessed the effectiveness of its global supplier management approach and, to some degree, went back to basics to establish the right foundations.

AstraZeneca (AZ) is one of only a handful of pureplay biopharmaceutical companies to span the entire value chain of a medicine – from discovery, through early- and late-stage development, to manufacturing, distribution, and the global commercialisation of primary care and specialty care medicines that transform lives. AZ is a global company with the need for a constantly evolving and effective procurement and supplier management strategy.

AZ employs around 51,500 people worldwide: 34.8% in Europe, 21.7% in North America, 6% in Central and South America, 4.1% in the Middle East and Africa, and 33.4% in Asia Pacific. Manufacturing in 16 and working in 100 countries, their medicines are used by millions of patients worldwide. In 2013, global sales totalled $26 billion.

In this case study we talk to John Hudson, Supplier Management Leader at AZ to learn how they reshaped their approach to procurement and supplier management globally, and how they went back to basics to ensure the right foundations were in place.

John has been Supplier Management Leader at AZ. He is responsible for the management and development of AZ’s procurement methodology (now called iProcure). Over the past two years, John has led a refresh and re-launch of this methodology and its ongoing roll-out has positioned AZ amongst the emerging leaders in our recent SRM studies.

We put a number of questions to John to discover how AZ has approached this challenge, what progress has been made so far and what the future holds.

Q: Firstly, when did AZ first adopt SRM? Or what they considered to be SRM?

John Hudson: The gradual evolution and improvement of AZ’s procurement and supplier management capability had been happening for many years. Global Procurement launched a new Supplier Sourcing and Management Framework (SSMF).

This framework was the first attempt to put in place a global standard for procurement and supplier management activity. While we succeeded in deploying SSMF globally, it became clear there were issues with local commitment, interpretation and capability that meant it was not consistently adopted. A decision was taken to re-evaluate our approach in order to drive greater adoption and consistency in its application.

Q. What was the catalyst for initiating the review and change of approach?

JH: This is where our Group Internal Audit function played an important role. As part of a review of AZ’s approach to procurement and supplier management activity, they reinforced the fact that SSMF was not being consistently applied. In parallel, there was an increasing need within the business to drive greater value from the management of key suppliers through the lifecycle, as opportunities to realise savings from sourcing activities became more challenging. It was clear our strategy would need to evolve if we were to realise more value post contract award.

Q. When did the review start? And how long did it take?

JH: We were conscious that many companies had been starting or restarting their SRM initiatives, which we felt had led to a level of fatigue amongst suppliers. To overcome this fatigue, we took time to research best practice and ensure we took a measured approach to changing our framework. Equally, it was important to recognise where changes were not required. The SSMF methodology had many components that were working well and we did not want to lose them. Consequently, the review and refresh of our approach took around six months, with the launch of the new iProcure methodology taking place.

There was an increasing requirement to release greater value from the lifecycle management of key suppliers.

Q. What were the most significant changes?

JH: We took the time to understand and learn from other companies’ experiences; through networking and making use of research tools we had access to. However, one of the most important things we did was to talk to and listen to our own people. We met with key stakeholders and procurement practitioners to understand the reasons why the SSMF methodology had not gained wider acceptance by the business and become embedded.

This vital feedback enabled us to pinpoint three key attributes the new approach required:

-

Simplification, while maintaining process integrity

-

Flexibility, to enable users to be agile and responsive to business needs

-

Focus, to allow our limited resources to align to the activities that added the most value

We asked John to expand on these attributes of simplification, flexibility and focus a little.

JH: I believe fundamentally that a process should be as simple as it can possibly be. Most organisations have to accommodate any new activity with existing resources. In AZ, supplier management tasks are the responsibility of procurement or business based practitioners whose capacities are limited. Therefore, AZ’s revised process has to support users to identify and deliver key tasks as efficiently and effectively as possible, without adding any unnecessary complexity.

AZ is a large and complex global business with operating units, functions and people who have different needs. We realised that to effectively embed a single, standard, global way of working across this diverse network, it would have to have inherent flexibility built into it. This flexibility then enables the procurement practitioner to be both responsive to business needs and maintain compliance with the spirit of iProcure. Importantly, this then enables them to maintain strong relationships with important suppliers and the support of their key stakeholders. Ultimately, users need the framework to quickly guide them to make informed choices about what is the best approach for them, their stakeholders, their suppliers and AZ.

As I mentioned, this new approach to supplier management is being delivered by people who are already busy and available resource is scarce. Therefore, it makes sense to prioritise and focus that resource on the supplier relationships that will make the most difference to our business.

Q. Did you find you had to redefine SRM?

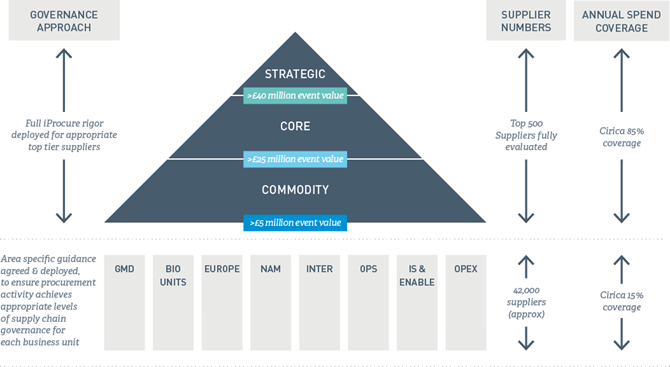

JH: No, I don’t think we had to redefine supplier management, neither in terms of what it meant to us nor the activities contained within it. What we did do was redefine how it would be applied through more effective supplier segmentation and increased focus and prioritisation. Consequently, this means supplier management can now be more effectively applied where it has the potential to add the most value.

Q. What do you consider was the most important part of your revised approach, apart from more effective segmentation?

JH: I think defining the right governance model for our prioritised suppliers was the logical next step. In doing so, the model had to set clear expectations of what is needed, while remaining relatively simple and flexible. This meant difficult choices around when a supplier would be in scope; with a new threshold for inclusion being set for contracts over $5M, which was a significant increase on the previous threshold of $250k. We combined this spend evaluation with a category criticality assessment to give a combined spend and criticality output. This refocusing enabled us to successfully identify which relationships were the most important to us and how we should try to manage them. So, to a certain extent, it has meant going back to basics in order to build a solid foundation from which we are now looking to deliver more value with these suppliers.

Q. What have you worked on apart from the governance model?

JH: We did a lot of work on creating new guidance materials that would help users determine the right approach to take. This was coupled with the development of new tools and templates to aid information capture. We then needed to inform users of the changes, which required a global training programme. All of the new guidance materials are available through our portal. We have also commissioned some changes to our Ariba technology platform to support the new process.

Q. How did you approach the re-launch and what were your major challenges?

JH: We started the re-launch and there were numerous challenges, not least of which was scale. We were ambitious in looking to achieve global coverage across the AZ procurement network. To date we have trained over 450 procurement staff in the new ways of working. We have also invested heavily in stakeholder management across all of the associated business areas. The approach we adopted required a lot of work to coordinate the launch across multiple business areas and geographies in parallel. Centrally we provided the process materials, communications and coaching. This was supplemented by creating a network of local champions who played an important role as ‘process ambassadors’ in each of their local groups. There’s no disguising the fact it was, and continues to be, a lot of hard work due to demand for ongoing user coaching or new hire training. However, the resulting governance baseline means supplier management is now prioritised and levels of adoption continue to improve in each of the business units.

Q. How does that prioritisation manifest itself? Is it measured? What have been the benefits?

JH: The adoption of this simplified approach is consistent with our measured approach to establishing and building from a strong foundation. We have a very clear view of external spend that is within the scope of our supplier management programme. Associated value delivery is tracked on a global basis; this continues to highlight the fact that we have more to do in this area to deliver what is required. These elements are measured on the global procurement scorecard and this has been an important step in ensuring user engagement. Having key governance metrics tracked at the highest level, sets the right tone from the top and helps users to engage with the importance of the activity. I believe AZ now has a solid supplier management foundation in place and a roadmap to ensure we achieve the delivery of increased value going forward.

Q. What does AZ consider the most exciting

value opportunities going forward?

JH: We are now well positioned and very keen to explore the broader value proposition of supplier management. We recognise that an effective supplier management programme opens up other key value streams which we need to capitalise on; notably innovation, increased pace of delivery and speed to market, improved quality, and better supply performance.

Q. What are your goals?

JH: The importance of broader value delivery through supplier management combined with increased functional efficiency is a primary goal and beyond, as we continue to evolve and improve our methodology, tools and capability. Ultimately, this will come from the continued adoption and embedding of good practice supplier management.

Q. How would you summarise the last two years?

JH: In summary, I would say the critical question we asked ourselves is ‘what are we trying to achieve and how do we do this consistently given that we have limited time and resources?’ As a result, we’ve embraced the need to take a more pragmatic approach; one that the business buys into and one that can support the obvious resource constraints we face. We now have a robust and effective global governance model, which helps us achieve our aim of good practice supplier management in the future.