Is RFP the wrong tool for the job?

Alan Day, Chairman and Founder of State of Flux

It’s been over 20 years since I was first involved in strategic sourcing and, in particular, running a formal RFP. That scary thought got me wondering why we, as a procurement industry, still rely on such an outdated technique to choose our suppliers and supplier partners.

The most common complaint I hear from procurement departments is that they don’t get involved early enough in the process, leaving little ability to influence the ‘demand’ or specification of the product or service.

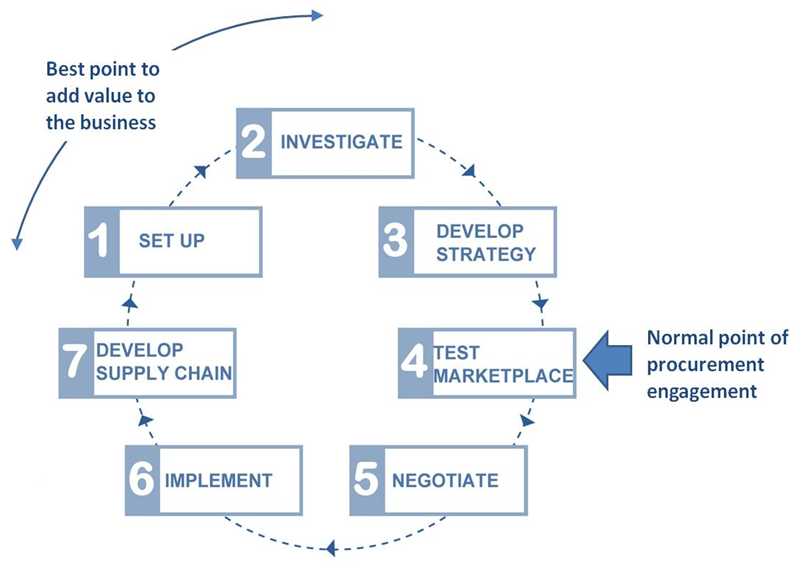

The strategic sourcing process (note - the RFP is usually produced during step 4)

While I completely agree procurement can add value by offering a commercial challenge to the business requirements and I see the strategic sourcing process as key to doing that, I can’t help thinking we are focused on the wrong things within the strategic sourcing process. Surely the focus should be on picking the right supplier to partner with us; the right supplier who is going to work together with us, adapt to changes in demand and specifications, and the right supplier who is focused on adding value to our business. Rather than putting the focus or emphasis on writing and running formal RFPs.

Think of the (total) cost

The irony is that procurement is a department that exists to make organisations operate more efficiently and effectively, and yet how many people have looked at the costs and delay added by running a formal RFP? The amount of time, effort and resource that is spent creating, running, answering questions and scoring formal RFPs can be significant. This impacts not only our organisation but all those suppliers responding, and we all know they will look to recoup these costs somehow.

It is no surprise that suppliers do look at the cost of responding to the bid and how much effort they want to put in versus the likelihood of winning. This may lead to selecting the supplier that was willing to invest more in the RFP response rather than the one that is the best partner or even the best to do that point specific task.

It is surprising that suppliers don’t ‘no-bid’ more of the RFPs they receive. The RFPs where procurement hasn’t had any contact with the supplier prior to sending out the RFP, the RFPs that don’t consider the impact on the suppliers' timelines or resource / costs required to respond, and the RFPs where they are clearly there just to ‘make up the numbers’ and prove procurement has been through a process. Suppliers know that no-bidding an RFP that you have spent months creating will be seen negatively (it’s been likened to invoke the same reaction from procurement as telling them their baby is ugly), and could affect the overall relationship and their future opportunities for business.

So why do we do it?

No one is arguing the need for competition and competitive negotiations while utilising the strategic sourcing process, but procurement should be looking at what the business is trying to achieve and how the RFP fits into this (or not). That is; is the formal RFP the right tool for choosing the right relationship to work with, ensuring the best value for the company, and having an auditable and transparent process to show that a sensible decision was made?

I believe as a procurement industry we have ended up making the formal RFP the central and most visible output of procurement. It’s a tangible activity, and both the business and suppliers can see our input in this process, which makes it easy to ‘sell’ what we do. Rather than the more intangible ‘we provide a commercial challenge to demand and specification’, or ‘help enable the buy-sell relationships between our business and the suppliers’, or other such mission statements which are much more difficult to understand and get buy-in for.

Being positioned as the department that runs RFPs, gives procurement a problem when trying to sell its strategic value. The business doesn’t always see the value we add on the commercial side of a supplier deal, but they recognise that if you want to run an RFP you go to procurement. Hey, we’ve even put rules in our corporate governance to state that over certain thresholds the business must come to us to run a formal RFP. In the eyes of the business we’ve commoditised ourselves... we’re now an RFP factory.

I can hear some of you disagreeing with this, and yes there are cases where procurement is adding significant value to the business by changing the way the business operates or challenging demand and specification. But let’s face it, despite best efforts, most of the time procurement is still being involved in only running the RFP and negotiations, too late to significantly affect the outcome.

Just as we want the business to see us adding value, we also want suppliers to see us as a

customer of choice. As such, these suppliers will be willing to bring new innovations, give us access to scarce resources when times are tough, access to preferential pricing and ensure their ‘A team' are focused on adding value to our business.

Why a supplier would view you as a customer of choice

Over the last five years of conducting our

global SRM studies, we have found there are three key attributes on why a supplier views you and your business as a customer of choice:

-

Money - they are going to either earn good revenue or margin on your account

-

Brand - they would like to align to your brand or have your brand on their corporate CV

-

Behaviours - you are good / easy to work with, you listen, and there is mutual respect

I find these interesting, especially when you look at the three attributes in more detail.

Money – Most suppliers are very focused on winning your business and the new account, but once this becomes ‘business as usual’ the attitude changes. The best way to look at this is to think of your salary. It’s what you deserve to get paid; you do a good job, you deserve to be paid. It’s the same for the supplier; they do a good job and they deserve to be paid. Money is not a motivator, but get the money wrong and it’s a big de-motivator.

Brand is similar; suppliers are focused on getting your brand on their ‘corporate CV’ but once they have the work / contract then they have it. It no longer becomes the motivator that it once was.

Which leaves us with behaviours, and you have to ask yourself, is running a formal RFP making you easy to work with? Is running a formal RFP a way of developing mutual respect? Is running a formal RFP the best way of demonstrating customer of choice behaviours? In these days of speed and mobility, why do we still spend months creating monolithic documents that take a large amount of resource from us and the suppliers to create and respond to?

Jamie Napper, Head of Sourcing and SRM at Carphone Warehouse Groups’ Connected World Services is forthright in his views that procurement is not just about selecting the right price and the right product - these things are a given. Moreover, it is about looking past the ‘deal’ and selecting, then developing the right supplier relationship. Jamie maintains that his team “will add more long term value to the business if it focuses on how the relationship will work, the governance structure, the metrics and the respective parties' roles and responsibilities than running a drawn out and formulaic RFP process”.

In fact, often the formal RFP process destroys value and supplier relationships more than it adds value. Access to innovation, one of the key customer of choice benefits, often loses any competitive advantage because rather than recognise it for what it is - ‘gold dust’ - we decide to ‘level the playing field’ and issue a formal RFP using these ideas, to the supplier and their competitors. This often restricts the supplier on how they respond to questions, giving them little or no opportunity to show how they can add value or differentiate.

In my view, suppliers that are offering innovation and adding value through different ways of doing things should be nurtured and encouraged. All procurement succeeds in doing by commandeering these types of supplier innovations, is running the risk of ruining the relationship and guaranteeing that the supplier will never proactively bring an innovation to the organisation again.

I was lucky enough to spend time with the very forward thinking Bobby Dhanoa, Global Head of IT Procurement at BP. Bobby was rightly questioning the value of the RFP in IT, especially when they were looking at the type of new suppliers they were trying to attract. She believes that these young, often small, dynamic and nimble organisations don’t want to and won’t go through the old style RFP process, preferring to deal on relationships and trust. We need to find a way of engaging with these suppliers, ensuring we do our due diligence, protecting our company without making it onerous, and maintaining or even building the relationship.

I think the Government may have got it right; the competitive dialogue process allows a formal process but retains flexibility and an informal ‘personal touch’, giving you the opportunity to build rapport and trust with the respective suppliers. Yes, we still need to capture our decision making process for audit purposes but why can’t we just video these sessions?

Procurement must be a department that is continually focused on adding value to the organisation and challenging ways of working. We want to ensure that we help our internal business stakeholders achieve their goals and targets while, at the same time, taking the opportunity to challenge total cost, facilitate customer of choice benefits like access to innovation and manage risk. While I’m a big supporter of the strategic sourcing process, I just don’t think the formal RFP is the vehicle to do this anymore. The procurement profession needs to look at itself and start employing more modern collaborative techniques, like the competitive dialogue process, to achieve its goals.

Six challenging questions to ask before running an RFP

-

Are you trying to find a ‘point solution’ or choose the best partner?

-

Do you know and can you justify the time and cost of running an RFP?

-

How would running an RFP be perceived by the supplier base and is the behaviour what they would expect from a ‘customer of choice’?

-

Are you reviewing the right suppliers or are you wasting some of the prospective supplier’s time?

-

Is there innovation that you need to protect or attain?

-

Are you betraying a supplier's trust by sharing the innovation with their competitors and are you prepared to ruin the relationship?

Please contact us on +44 (0)2078 420 600 or email us at enquiries@stateofflux.co.uk if you have any questions or would like to discuss anything further.